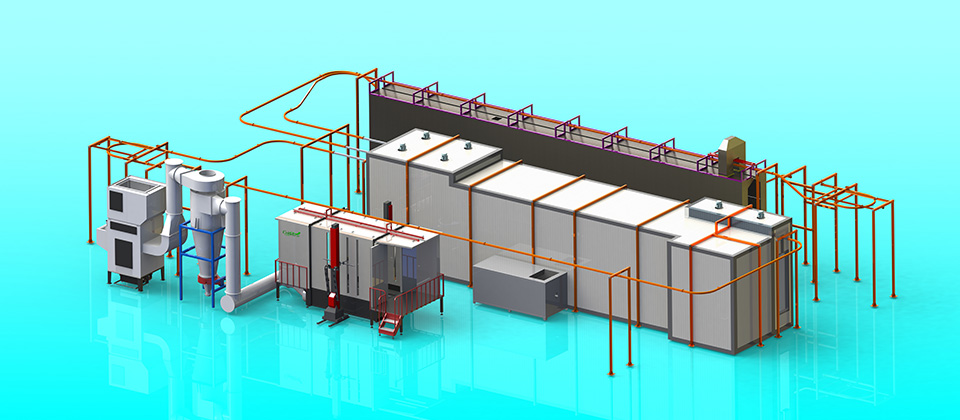

Full Automatic powder coating line mainly consists of pre-treatment line, moisture drying, powder coating equipment, high-temperature curing equipment, etc. The whole line is designed according to customer needs. We can not only provide a wide range of powder coating line (whether relatively simple manual powder coating system or complex, programmable automation system), but can also provide the industry’s unmatched expertise and ongoing support.

Various metal products, stainless steel products, aluminum profiles, etc. surface powder coating.

Full Automatic powder coating line mainly consists of pre-treatment line, moisture drying, powder coating equipment, high-temperature curing equipment, etc. The whole line is designed according to customer needs. We can not only provide a wide range of powder coating line (whether relatively simple manual powder coating system or complex, programmable automation system), but can also provide the industry’s unmatched expertise and ongoing support.

1.The coating quality meets the coating standards for commercial shell and sheet metal parts.

2.The pretreatment adopts the chemical treatment method of the joint cleaner to remove the oil stain on the workpiece surface, form a good phosphate film, and improve the binding force between the workpiece surface and the powder coating.

3.In order to save water, all washings use a multi-stage countercurrent process. In order to improve the effect and quality of the shower treatment, degreasing is equipped with a heating device to improve the treatment effect of the degreasing liquid.

4.In the layout of the production line, follow the principle of smooth flow of the process route and short logistics route, and conduct equipment layout and general drawing design.

5.Moisture drying oven, powder curing oven: using gas heating (hot air convection cycle) drying furnace, furnaces using bridge structure, high energy efficiency.

6.Electrostatic powder spraying complete sets of equipment: using domestic quality and high-quality powder spraying complete equipment, automatic powder spraying, manual supplemental spraying, adopting a large cyclone plus secondary filter cartridge recovery system, which can be quickly separated.

7.Mechanized transport equipment: Considering the adaptability to the production batch and the flexibility of production and the convenience of the upper and lower parts of the workpiece, the design of the coating line adopts an assembly line production operation mode. The workpiece conveying is completed by the QXG-250 suspension conveyor, controlled by the PLC, and the degree of automation high.

8.The production line fully considers equipment energy saving, labor protection, environmental protection and fire safety, and complies with the coating operation safety regulations and related standards.

9.The supporting facilities such as fire protection, environmental protection, and three-waste treatment should be implemented at the same time (self-owner).

10.The coating process compares the characteristics of similar projects at home and abroad, with the principles of complete processes, advanced technology, high degree of automation, and economical rationality. It adopts typical, advanced, and mature production processes to build a coating production line that exceeds the quality of similar products in the industry.